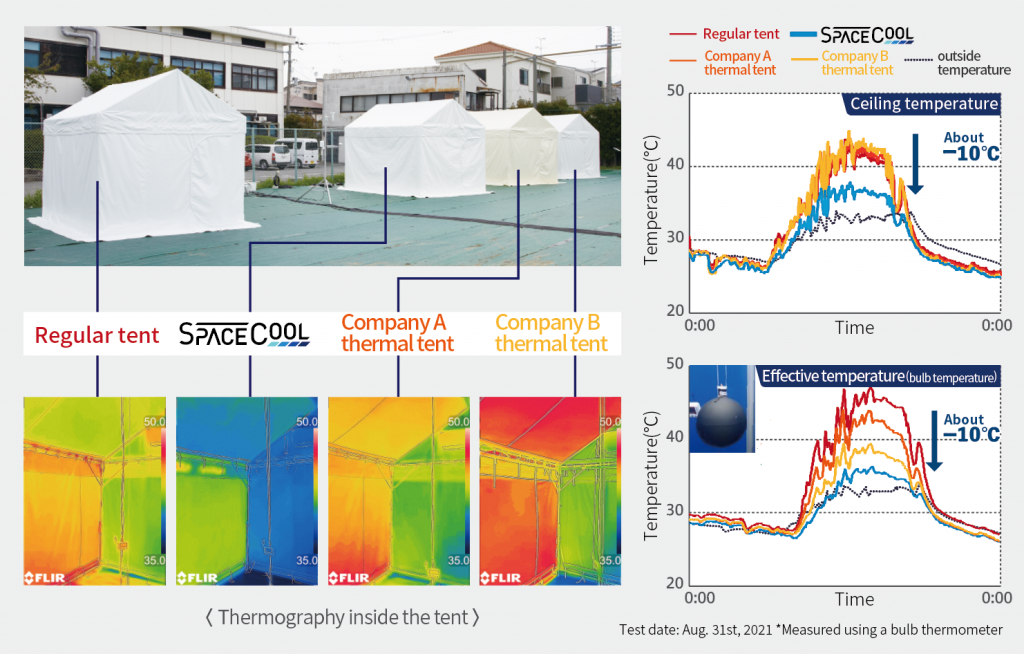

Increase in heatstroke risk from rising indoor temperatures in summer

- Helps lower WBGT and support MHLW-defined workplace heatstroke measures

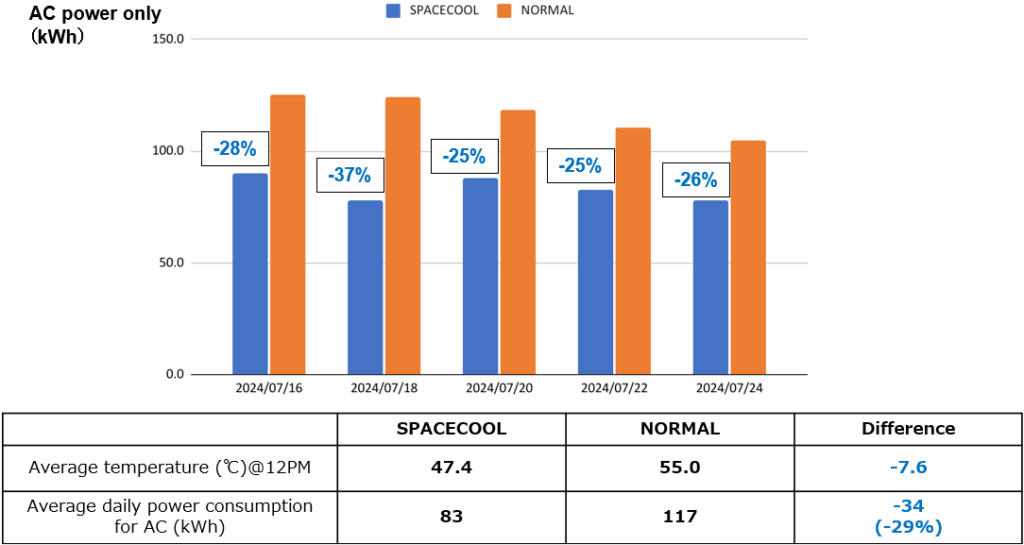

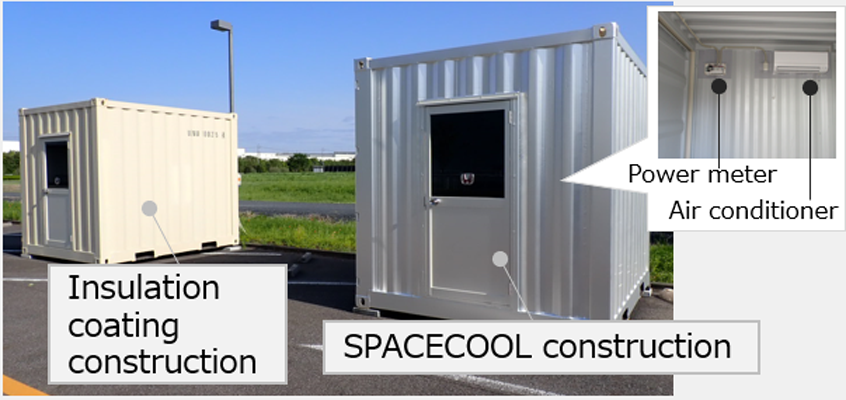

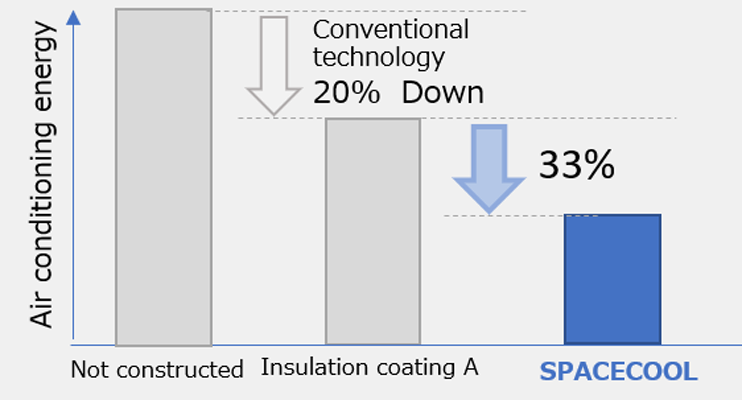

Unit houses, containers, etc.

Improving comfort and safety, and contributing to climate adaptation and mitigation.

SPACECOOL supports society and people through a wide range of applications.