The failure rate and life of electric/control and broadcast devices are strongly affected by heat around.

Current thermal issues and solutions with SPACECOOL

Internal electric/electronic devices deteriorate/fail

Device life ⬆

Maintenance cost ⬇

Measurement errors occur

Trust in measurements lost

Less measurement error

Increased trust

Cooling requires energy consumption and CO2 emissions

Cooling cost ⬇

CO2 emissions ⬇

Common outdoor unit insulation/heat release/cooling device issues

【Shade board】

●When a heating element is present, heat builds up

●Once heat builds up, it’s hard for internal temperature to drop

【Cooling fan】

●For air intake Sucks in dust, humidity

●Regular maintenance is necessary

-1.jpg)

【Cooler】

●Needs electricity

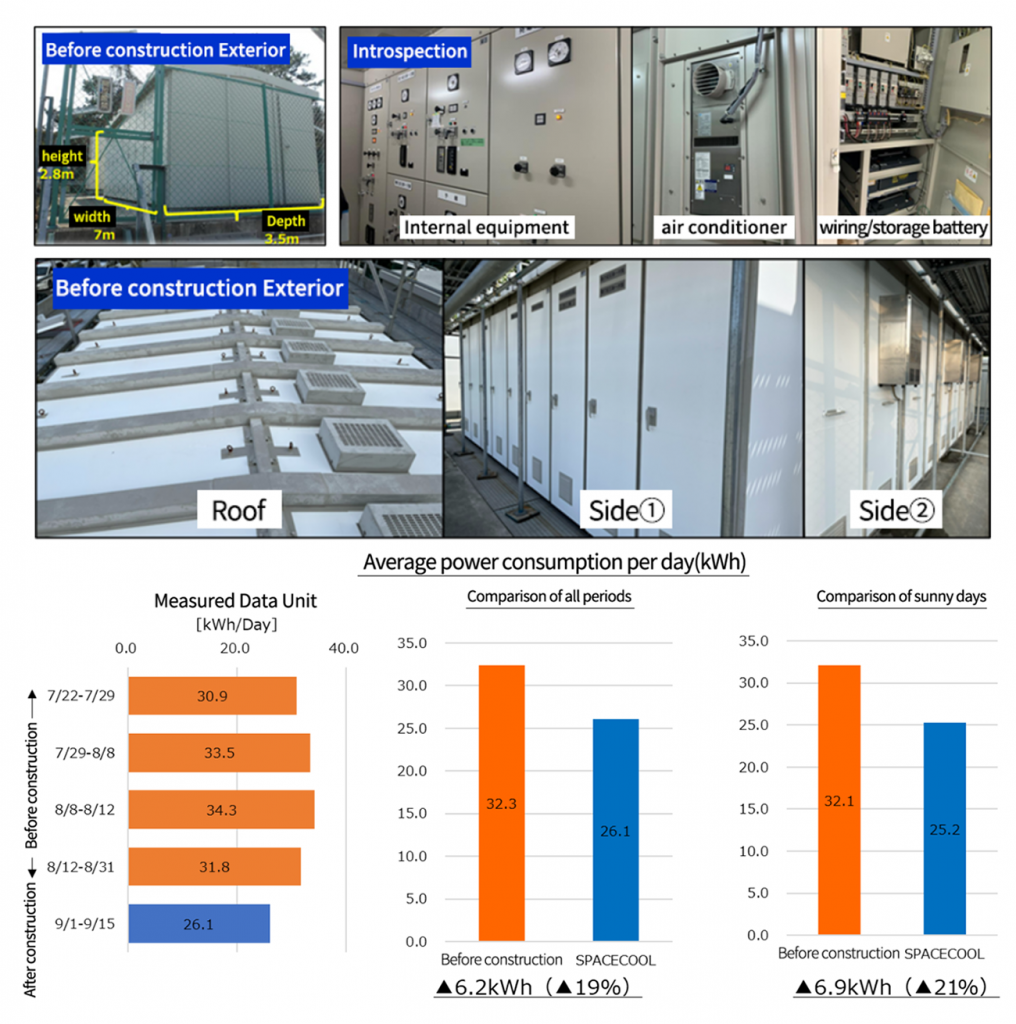

Introduction example and effect of high voltage receiving and transforming switchboard

Air conditioning power consumption is reduced by approximately 21% on sunny days and by approximately 20% over the entire period, including rainy and cloudy days.

<Test conditions>

Test date: Measured the power consumption reduction effect over the entire period from July 22nd to August 31st before construction and from September 1st after construction.

Installation location:SPACECOOL is installed on the roof, east, west, south, and north walls.

Internal storage equipment:Vacuum circuit breaker 3.6kV 600A x 6 units

Molded transformer 3Φ3.3kV/210V 100kVA x 1 unit

Molded transformer 1Φ3.3kV/210-105V 100kVA x 1 unit

DC power supply 2.6kVA x 1, storage battery MSE 50Ah @ 10 hour rate 54 cells (MSE-50-12 x 9, DC108V/set)

Air conditioner capacity 1Φ100V 615W×3

<Test results>

As a result of monitoring air conditioning power consumption with and without this material, it was confirmed that air conditioning power consumption was reduced by approximately 21% on sunny days and by approximately 20% over the entire period, including rainy and cloudy days.

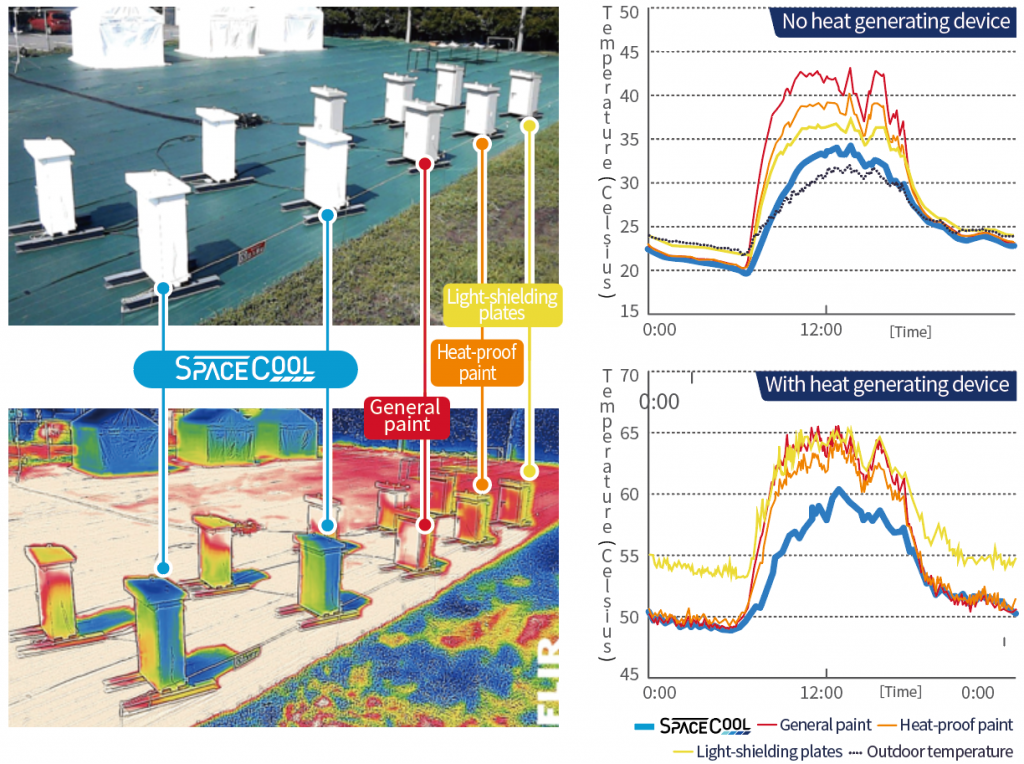

Examples of introducing electronic control panels and their effects

Reduces the temperature inside the electronic control panel by approximately -10°C

<Test conditions>

Test date:9/21/2021

Internal heat source:Device modeled after an inverter (200W)

Size:H1000/W600/D300

<Test results>

No heating element:Roughly 10℃ cooler than regular paint, Confirmed to be 5℃ cooler than douser.

Heating element present:Roughly 10℃ cooler than ordinary paint, Roughly 8℃ cooler than douser.