Internal electric/electronic devices deteriorate/fail

- Device life

- Maintenance cost

Cubicles, HVAC systems, control panels, etc.

-1.jpg)

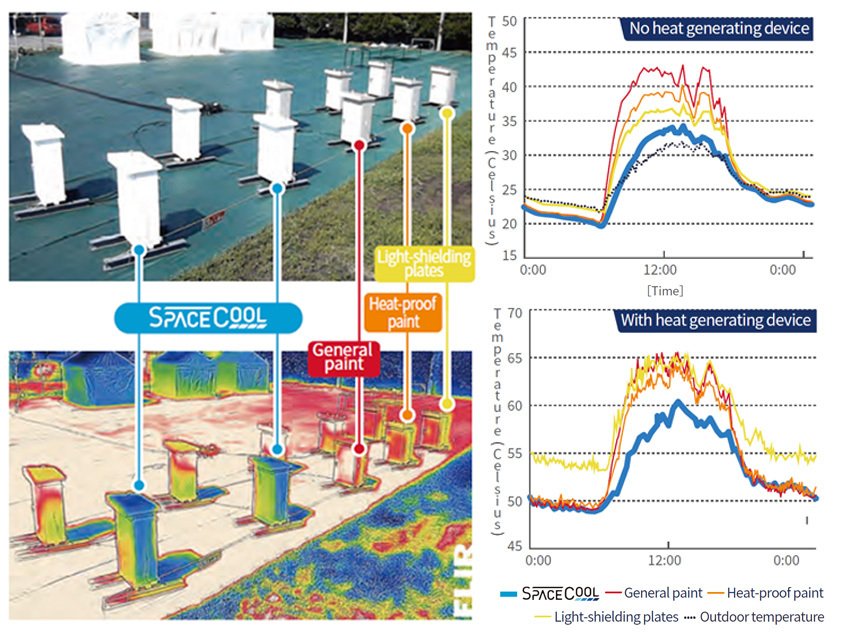

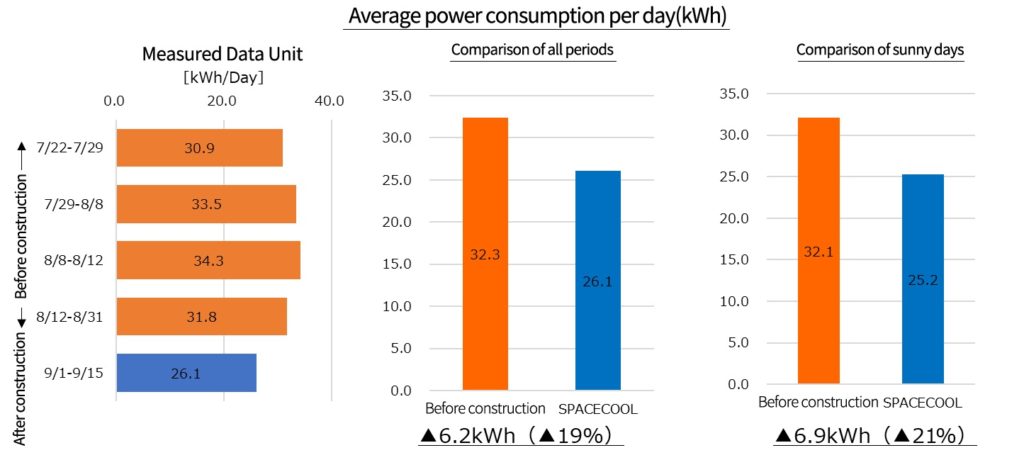

Improving comfort and safety, and contributing to climate adaptation and mitigation.

SPACECOOL supports society and people through a wide range of applications.