Our new material creates comfortable cooling while avoiding over reliance on using energy like electricity.

Protect important things from heat and allow everyone spend their days comfortable and safe.

Film

Main Features

(1) World’s highest level of reflectance and radiative cooling performance

(2) Maintains long-term effects with excellent outdoor weather resistance

(3) Flexible optical film may be used and applied for a variety of purposes.

Summer performance of the radiant cooling material lowers 2-6°C below the outdoor air temperature, and the cooling capacity is 70-100 W/m2, providing coolness as a sensory temperature.

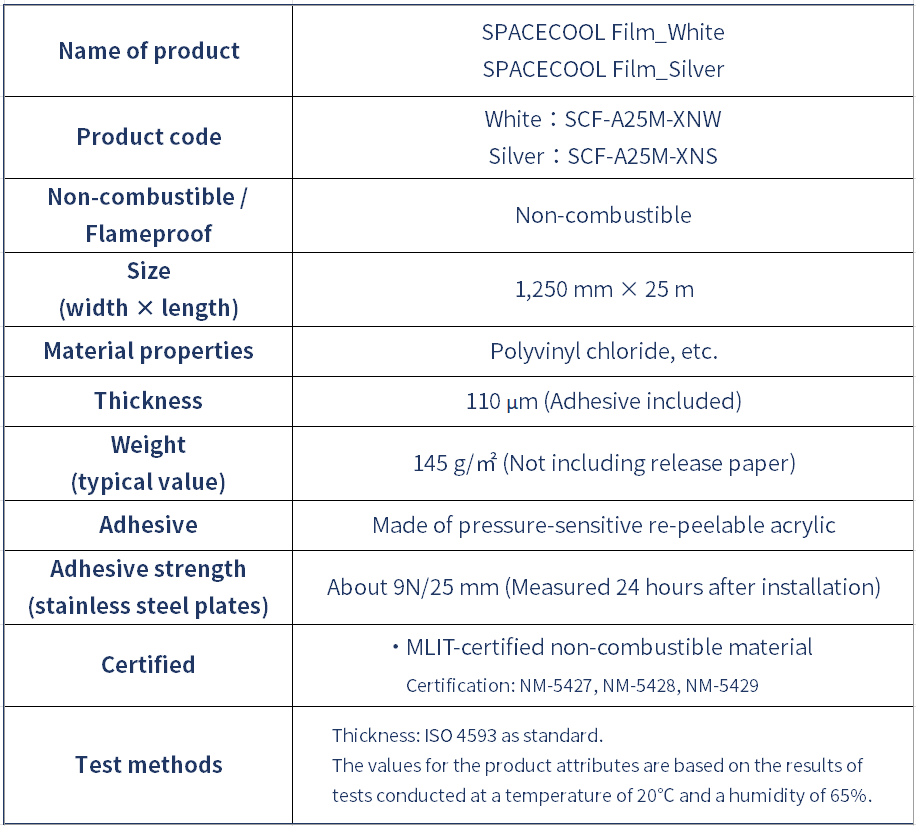

Product Overview

【Non-combustibility】

This product has passed the performance evaluation for non-combustible materials (metal plates, excluding metal plates,

aluminum plates) based on A rticle, Item 9, of the Building Standards Act (Act No. 201 of 1950). *¹

・NM-5427 (synthetic resin film clad/non-combustible material (excluding metal plates))

・NM-5428 (synthetic resin film clad/non-combustible material (metal plates))

・NM-5429 (synthetic resin film clad/aluminum alloy plates)

*¹To be recognized as a non-combustible product, this film must be installed on construction materials listed in "Stipulations for Non-combustible Materials " in the Ministry of Construction Public Notice No. 1400 issued on May 30th, 2000, or base materials listed in the appendix o tfhe certificate.

*Edge treatment is required to ensure the prolonged use of SPACECOOL products.

*In order to improve product design and specifications,changes will be made without any prior notice. We kindly ask for your understanding.

*The above physical properties are initial measured values, not guaranteed values.

This product has passed the performance evaluation for non-combustible materials (metal plates, excluding metal plates,

aluminum plates) based on A rticle, Item 9, of the Building Standards Act (Act No. 201 of 1950). *¹

・NM-5427 (synthetic resin film clad/non-combustible material (excluding metal plates))

・NM-5428 (synthetic resin film clad/non-combustible material (metal plates))

・NM-5429 (synthetic resin film clad/aluminum alloy plates)

*¹To be recognized as a non-combustible product, this film must be installed on construction materials listed in "Stipulations for Non-combustible Materials " in the Ministry of Construction Public Notice No. 1400 issued on May 30th, 2000, or base materials listed in the appendix o tfhe certificate.

*Edge treatment is required to ensure the prolonged use of SPACECOOL products.

*In order to improve product design and specifications,changes will be made without any prior notice. We kindly ask for your understanding.

*The above physical properties are initial measured values, not guaranteed values.

Main Applications

Outdoor equipment

Outdoor panels, storage batteries, cubicles, base stations

By installing it on the roof and exterior wall surfaces, it is expected to suppress the deterioration of electronic devices due to solar radiation and internal heat generation, and to reduce failure problems and maintenance costs.

By installing it on the roof and exterior wall surfaces, it is expected to suppress the deterioration of electronic devices due to solar radiation and internal heat generation, and to reduce failure problems and maintenance costs.

Transportation

Truck beds, buses, etc.

By applying it to the exterior of mobility and air conditioners, the inside of mobility is cooled, Fuel efficiency is also expected to improve by eliminating heat problems and improving air conditioning efficiency.

By applying it to the exterior of mobility and air conditioners, the inside of mobility is cooled, Fuel efficiency is also expected to improve by eliminating heat problems and improving air conditioning efficiency.

Architectural structures

Large-scale facilities such as factories, warehouses, airports, etc.

By installing on the roof and exterior walls, heat input due to solar radiation is minimized, and the interior space can be cooled with zero energy.

It improves air conditioning efficiency and is expected to save energy and reduce CO2 emissions.

By installing on the roof and exterior walls, heat input due to solar radiation is minimized, and the interior space can be cooled with zero energy.

It improves air conditioning efficiency and is expected to save energy and reduce CO2 emissions.

Temporary materials

Unit house, tent warehouse, container, etc.

By installing on the roof and exterior walls, heat input due to solar radiation is minimized, and the interior space can be cooled with zero energy.

It improves air conditioning efficiency and is expected to save energy and reduce CO2 emissions.

By installing on the roof and exterior walls, heat input due to solar radiation is minimized, and the interior space can be cooled with zero energy.

It improves air conditioning efficiency and is expected to save energy and reduce CO2 emissions.